Izolex Sp. z o.o. have been providing building chemicals since the year of 1993. Izolex product line includes hydro statical insulation light bodies Styrbit 2000® and Izobit-DK® for foundations, Cemizol 2EP® and Cemizol 2EN® for swimming-pools and terraces, Izofol® light body for shower rooms and Cemizol 2EN® for steamproofing and waterproofing in steam baths.

In addition, the product line includes elastic tile paving mixtures for terraces, swimming pools and damp rooms Cerakol® and Cerakol® Special both for ceramic and mosaic tile paving.

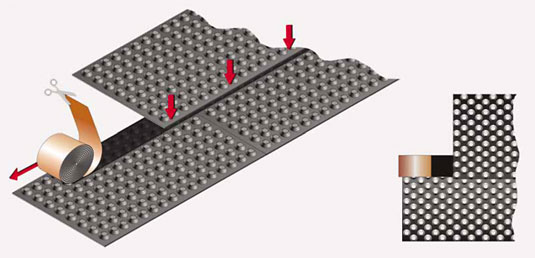

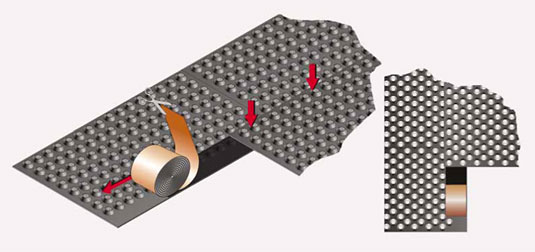

ISO-DRAIN® BUTYL STRIPS

INTERPLAST ISO-DRAIN® butyl strips are used to join protection and drainage sheets. Use of butyl strips system provides a durable connection between adjacent sheet sectors. Butyl strips provide a barrier against moisture.

Dimples on dimples connection

Dimples on flat boarder margin

NB! The first row of dimples must be covered with butyl strip!

Measures

Material thickness: 1,5 mm

Roll width: 40 mm

Roll length: 40 m

Package: 3 rolls in box

INTERPLAST drainage and protection sheets comply with DIN requirements. When installing, only original accessories must be used (see „Accessories”).

Find more about product on the Estonian data sheet ISO_DRAIN_20 ISO_DRAIN_BUTYL_STRIPS.pdf and from our sales representatives.

FEBSPEED PLUS

Chlorine-free, accelerating and enchancing freeze resistance powdered admixture

Product description

FEBSPEED PLUS rapidly increases setting-time in mortar and concrete and can be used to aid working in low temperatures.

FEBSPEED PLUS is developed for use in most concrete and mortar classes, where calcium chloride or based on it materials is not recommended or banned. Matches: ASTM C494: Type C

Fields of application

Improves resistance to cold weather: in concrete and mortar, when temperature is decreasing or likely to decrease below freezing-point.

Floor hardener: for concrete floors, should the floor be opened for trafficking in minimum time.

Chloride-free accelerator: in reinforced concrete, to ensure high early strength.

Features and benefits

- Chloride free

- Ensures high strength at a very early age

- Improves frost resistance when setting-up

- Increases density, pressure and tension resistance

- Improves workability

Find more about product on the Estonian data sheet Febspeed_plus.pdf and from our sales representatives.

FEBSET 45

Pre-mixed magnesia phosphate cement mortar for rapid high early strength repair

Product description

FEBSET 45 is a Specially formulated magnesia phosphate cement-based mortar for repair, with pre-mixed selected aggregates, which give controlled, extremely high early strength in temperatures ranging from -20 °C (or lower) up to 30 °C. FEBSET 45 is a modified compound with 10 mm agreggate for use in layers over 30 mm thick.

FEBSET 45 provides a repair material for concrete slabs, which reaches adequate strength for trafficking, or other use, at a very early stage. It is also suitable to use as a repair medium at low ambient temperatures.When FEBSET 45 is added to water and mixed, an exotermic reaction commences and within approx. 15 minutes (at 20 °C) setting process takes place. The material hardens at 15-20 °C to give sufficiently strength to hold heavy traffic in less than one hour.

Fields of application

For use in concrete repair situations, where the minimum of delay and work disrutpion of the utmost importance.

- Cold store floor areas.

- Concrete roads and nosings.

- Bridge decks.

- Quays/crane rails

- Industrial floor areas

- Loading bays and warehouses.

- Around fixing bolts.

- Raising and levelling manhole covers, gratings, hydrants, etc

Features and benefits

- High strength at a very early age (45 min).

- Minimum delay to traffic and production. When used to repair concrete pavings, it permits early re-opening to traffic – within 45 minutes at 20 °C.

- Excellent bond. No secondary bonding agents required.

- Highly durable. Excellent resistance to de-icing salts.

- High freeze/thaw resistance.

- No curing required.

- Can be placed in sub-zero temperature.

- Non-shrinkable

Find more about product on the Estonian data sheet Febset_45.pdf and from our sales representatives.

FEBOND SBR

Polymer admixture to improve bondability of cement mixtures and concrete and water density

Product description

FEBOND SBR is a styrene-butadiene co-polymer-disperse system, developed for use in cement mixtures and in concrete in damp conditions.

Used as an admixture to improve water density, abrasion resistance and workability/elasticity.

FEBOND SBR, combined with cement, provides an effective water resistant and reliable bonding layer.

Fields of applications

- Concrete repairs

- Floor screeds and toppings

- Exterior walls bonding and sole plate plastering

- Waterproofing and tanking

- Fixing stairs

- Corrosion protection of steel

- Silage pit lining and protection

Features and benefits

FEBOND SBR modified cement mixtures have the following advantages:

- Increased flexural strength

- Increased tensile strength

- In proper ratio significantly reduces shrinkage

- Prevents penetration of the second coat into rendering coat

- Lower water – cement ratio

- Increased durability and toughness, improved abrasion resistance. Good frost, abrasion resistance to waterborne salt penetration.

- Resistant to many chemicals and mineral oils.

- Excellent adhesion to steel and concrete. Sticks well to bricks, glass, asphalt, wood, polystyrene and most of the building materials

- Better corrosion defence

- Proved durability

- Thermal expansion and modal features similar to concrete.

- Approved for use in contact with drinking water (WRC certified – UK)

Find more about product on the Estonian data sheet Febond_SBR.pdf and from our sales representatives.

FEBMIX DH

Powder mortar plasticiser, forms air-bubble pores in concrete

Desription of product

FEBMIX DH is a powder mortar plasticiser for use as an alternative to lime or as a supplement to lime. Matches BS 4887.

Applications

For use as an admixture for mortars to improve their workability; will entrain up to 20% air bubbles into mortars in ordered structure optimising mixture ratio both for brick laying and plastering.

FEBMIX DH improves frost resistance in both freshly laid and hardened mortars; also enchances long-term durability of cement-sand and cement-sand-lime mortars and improves mortar workability (reference BS 5628 UK).

Features and benefits

- Economical:

– reduced labour costs,

– redused wastage,

– more accurate ratio of mixture. - Helps reduce efflorescence.

- Reduced bleed and segregation in the mix.

- Improved bond.

- Reduced shrinkage when hardened.

Technical data/typical properties

FEBMIX DH entrains microscopic air bubbles into mortars in a controlled manner as specified in BS 4887 (UK).

Mixtures with entrained air produce better workability, whereas amount of mixed water is reduced. FEBMIX DH also improves durability cold applied – both fresh and dry and hardened mortars as microscopic air bubbles provide space for water expansion due to freezing.

Find more about product on the Estonian data sheet Febmix_DH.pdf and from our sales representatives.

BASF Copnstruction Chemicals Ltd some time ago aquired FEB brand, which was started in the year of 1953 in England. FEB was a pioneer in the sphere of construction chemicals, when more than 50 years ago the first liquid mortar plasticiser was made. Continiously developing product line includes a lot of various construction chemicals: admixtures, flooring systems, reinforced concrete repair materials, tiling materials, waterproofing systems, roofing and repair materials, joint sealants, etc.

Cold bitumene mastics like FEB Aquaseal Hyprufe and two-component polymer mastic FEB Brushcrete have been popular in Estonia over ten years.

Rapidly laminating cement epasit sp

Application

epasit sp is rapidly laminating cement for installation work on concrete and masonry, flooring, on walls and ceilings.

epasit sp can be used concrete works and masonry in winter

Features

epasit sp is a ready-to-use, mineral, rapidly laminated, cold resistant and breathing cement. Non-agressive to iron.

Application

To clean substrate from dirt and loose particles. Dampen working area with water. Mix thoroughly with clean water until smooth paste consistence.

Vater amount: approx. 0,3 l/kg. Ready mixed material should be applied within 1 minute.

Water mustn’t be added to the solidifying material.

Solidification time: approx. 3 minutes

epasit sp can be also used as mortar for plastering or masonry work; in this case, add oven-dry silica sand or washed gravel sand. In case of a suitable filling material epasit sp is also applicable in concrete mixtures too: 2 parts of epasit sp and 1 part of silica sand, that is dry added before mixing. The ready-to-use mixture is obtained by adding ¾ parts of water.

Find more about product on the Estonian data sheet Epasit_sp.pdf and from our sales representatives.

Fine putty epasit sg

Application

epasit sg is developed for filling-up the sano-plaster epasit lpf, achieving fine finishing.

Features

epasit sg is a ready-to-use extra-fine white dry mortar.

epasit sg has low content of chromite and meets TGRS 613 / Giscode ZP 1.

Technical data:

Spreading density of fresh mortar: 1,7 kg/dm³

Spreading density of solidified mortar: 1,5 kg/dm³

Capillary water capacity: 0,4 kg/m²h½

μ-value: 16

sD-value: 0,016 m

Find more about product on the Estonian data sheet Epasit_sg.pdf and from our sales representatives.

Fine sanation mixture

epasit sef

Application

epasit sef is fine sanation mixture; developed for masonries and mineral plaster, especially for applying a thin coating of sanation plaster to epasit lpf in order to achieve fine surface structure (size of grain up to 0,4 mm).

Features

epasit sef is white mineral dry mortar, matching DIN EN 998-1, and it contains mineral adhesive compounds and filling material.

epasit sef has low content of chromite, thus meeting TGRS 613 / Giscode ZP 1.

epasit sef surbodinates to the in-business product line and the independent watchdog – building materials control and certification union (BÜV-ZERT) in Baden-Württemberg state.

Find more about product on the Estonian data sheet Epasit_sef.pdf and from our sales representatives.